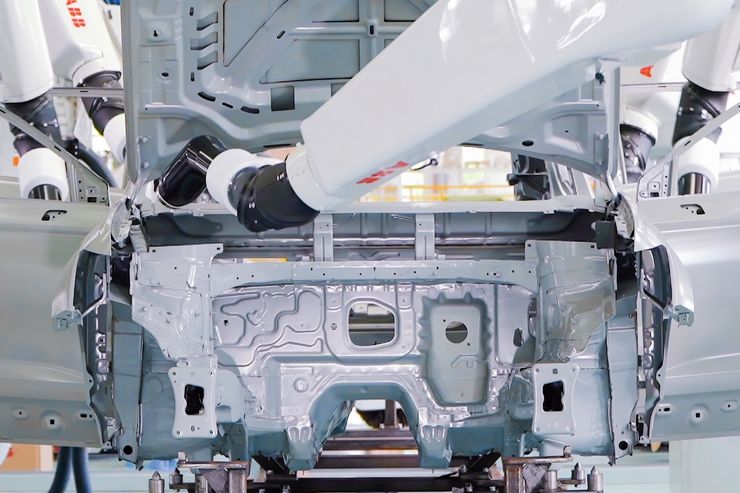

Reduced footprint, sustainable processes and great versatility – the demands automotive manufacturers place on their production are diverse. With a new interior painting solution ABB supports OEMs in achieving these goals. Compact Interior Paint offers a 33 percent reduction in footprint while lowering VOC and CO2 emissions. Moreover, it combines compactness, flexibility and overall effectiveness and covers a variety of vehicle types from cars and SUVs to large MPVs. Inside the compact station, four IRB 5350 robots open the doors and two IRB 5500- 22 robots open the hood and trunk. Key to the compactness of the solution, however, are the six new IRB 5500-27 7-axis robots, which offer a choice of floor, wall or inverted mounting options. Thanks to their 3.8-meter reach, they cover a very large working area across a car body, and their enhanced working angle reduces the number of robots required for a particular task. Furthermore, they offer great flexibility when it comes to painting tricky areas. All IRB 5500 robots used in the Compact Interior Paint solution share the same spare parts.

In the event of a failure another robot jumps in

To maintain productivity, one IRB 5500- 27 robot is able to temporarily take over the tasks of the one next to it. In the event of a failure, the remaining robot will enter degrade mode, either increasing speed or cycle time to cover for the failed robot until it can be brought back online. If, for example, the robot for the left rear door is not operational, the robot for the left front door will jump in, painting the rear door first and then the front door. The program for the doors on the other side of the vehicle remains unaffected. Hence, a possible failure of one robot can be compensated for by another installed robot. Another benefit of the large envelope is that the IRB 5500-27 is able to reach all surfaces to be painted without the need for a linear track. This eliminates additional maintenance tasks such as regular replacement of hoses in the drag chain of the exterior track, and cleaning is easier as well. The compact arrangement allows automotive manufacturers to gain floor space – no separate booth access area is required – without limiting the robots or losing space for larger vehicle bodies.

The complete article was published in IST 02/2021.

Autor(en): ABB Robotics Germany