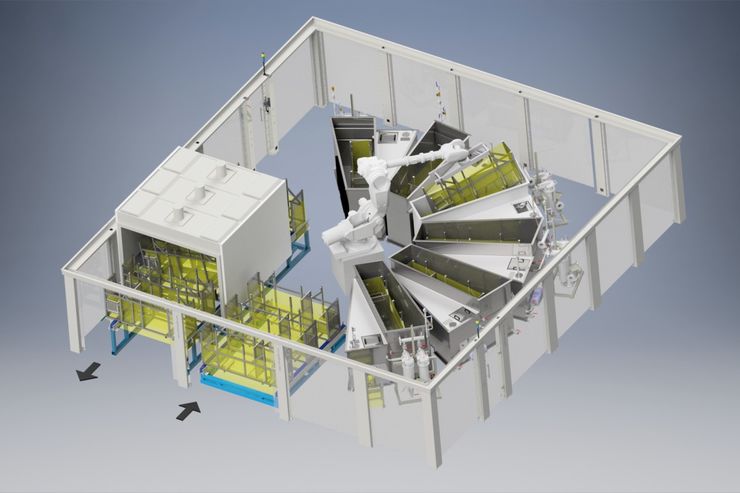

Aluminum as a material contributes in particular to weight reduction in vehicle construction, but is of course also used in other sectors outside the automotive industry. Whether body parts, housings for electric drives or battery trays - the problem with the assembly of aluminum parts is the natural, inhomogeneous oxide layer that repeatedly forms on the surface and has a disruptive effect on subsequent processes such as welding, bonding, painting or vulcanization. By applying a titanium conversion coating, the non-uniform oxide skin is removed and replaced by a durable and thin Ti layer. Corrosion protection is improved and the surface is optimally prepared for the application of paints and coatings. MTM has now supplemented the concept of its cleaning systems - in addition to degreasing, drying, high-pressure or brush deburring - with the option of surface treatment by Ti passivation. With the new RoboFlex system type, the supplier now realizes titanium coating and thus optimizes quality and safety within assembly production. Since the beginning of 2021, six systems of this type have already been successfully in operation at well-known automotive suppliers to both clean and coat titanium on structural parts and battery trays, among other things. According to MTM, the RoboFlex system complies with all new European environmental directives.

Autor(en): MTM