The Gema automation solutions offer the perfect combination of part detection system and axes to perfectly coat any objects, from simple to complex geometries and also XXL parts.

For coating of simple part geometries, an easy solution is the gap detection system. For this solution a sensor detects the object to be coated at the booth entrance and the guns are activated just before the object passes the axes system. In case of a gap, the guns are turned off.

In the case of different object heights, the appropriate solution is height recognition. A vertical light grid detects the object height and automatically triggers only the required guns. Thus, you save powder by applying it more effectively.

In addition to the gap and height detection systems, the width detection automatically adjusts the horizontal gun position according to the object widths.

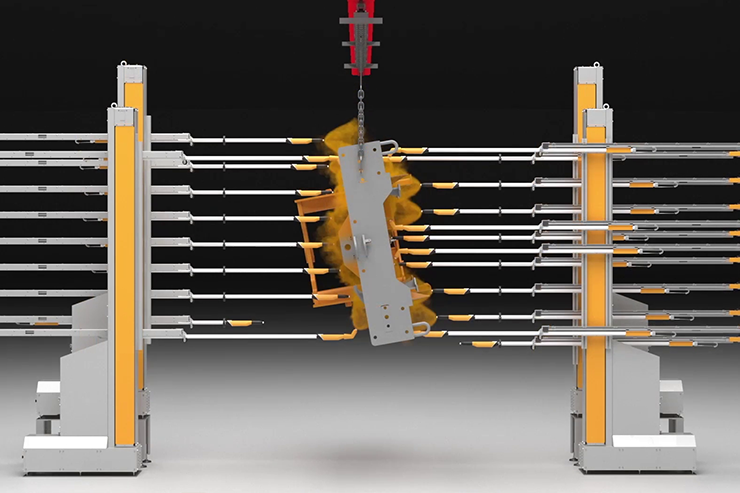

When coating complex geometries and XXL parts, the perfect solution is Dynamic Contour Detection. With the programming-free solution you literally "Scan & Spray". This sophisticated technology detects the object contour and geometry. Then, automatically adjusts each gun individually to the correct position and starts powder application without the need for programming.

With automation solutions from Gema you can achieve perfect coating results and a high level of process reliability for any complexity.

Further Information at www.gemapowdercoating.com.