15 years ago, Michael Eder revolutionized the coatings industry with a corrugated cardboard box. After long term development, his company Brainflash launched the invention in 2003: Paint mist separators in the form of cubes, made from 100 % recycled paper. The dry scrubbers absorb up to 100 kg overspray/m² and provide economical, environmentally friendly and ergonomic finishing in numerous international varnishing companies. Through the conversion from wet to dry absorption, chemicals are eliminated in the separation process and energy costs are lowered accordingly. Saturated edrizzi dry scrubbers are practically disposed of just like ordinary domestic waste, and thus reduce the amount of harmful varnish scrap, which is a cost-intensive special waste. The modular system enables an individual application in any kind of surface processing. The manageable cubes are assembled in the modular system to an optionally large separation area – no matter if used horizontally, vertically, or a combination of the two. Different sized modules make it easier to retrofit existing systems or install new systems in a shortage of space - adaptions in measurements are possible in special-purpose solutions. Eight different types of dry scrubbers and five types of complementing secondary filtrations cover all areas of application in the surface processing industry. All modules within the edrizzi system can be changed separately and economically when saturated. Due to the flexibility of the system, edrizzi is effectively applied in a variety of surface processing companies. From the smallest spray gun facilities with multi-year service life to ambitious automated paint shops. The paint mist separator level can be complemented by several follow-up filtrations. Especially in air circulation mode and top paint shops, those secondary filters are essential and important with regard to the development of emission control laws and environmental protection. There are indeed facilities which run without secondary filtration, because the dry scrubbers are able to absorb all of the overspray.

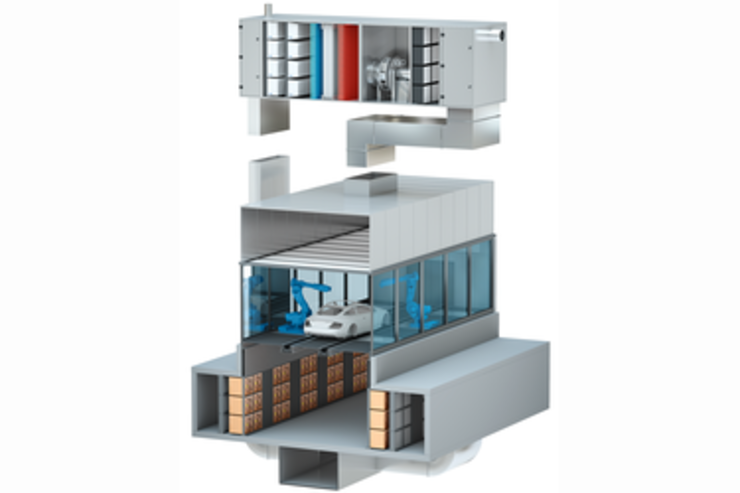

Picture:The illustration of a new plant in the automotive industry shows the system in air circulation mode and thus with several secondary filters.

Autor(en): Ke