Quality assurance of the paint stripping process plays an important role in returning incorrectly coated parts to the production cycle. The stripped parts should meet similar quality requirements as new parts in order to avoid contributing to coating defects again. In order to meet these requirements, it is important that external paint stripping companies as well as paint stripping departments within the coating companies work according to defined and controlled procedures. Sensitive substrates such as zinc or aluminium and the conversion or oxide layers on them can be easily attacked during the paint stripping process. Apart from the sensitivity of the respective surface and the suitability of the paint stripping agent, there are various possible causes from the process control such as too high alkalinity, water in the paint stripping medium, too long application time, too high a paint stripping temperature or insufficient rinsing. The resulting changes to the surface can lead to problems during the subsequent recoating of the parts.

Example: Paint defects due to salt residues from the rinsing process

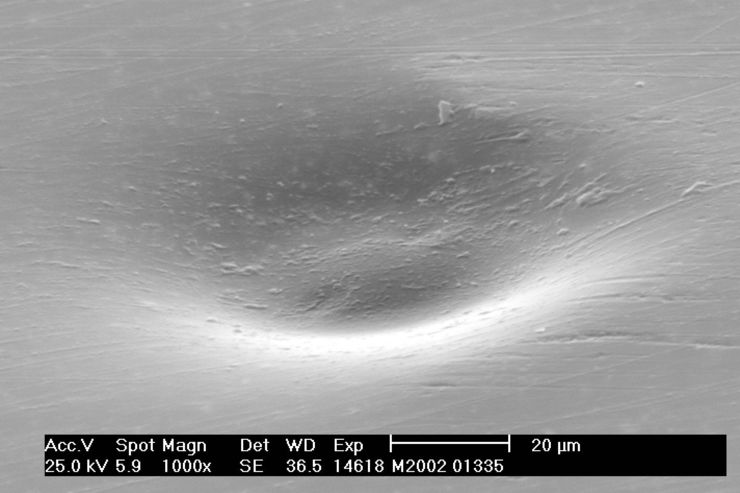

During the coating of stripped aluminium strips, there was an accumulation of paint defects in the form of craters and pinholes. Investigations with the scanning electron microscope showed that the paint defects were caused by dried up salts from the rinsing water after the alkaline activated paint stripping. Due to an insufficient pre-treatment of the strips before recoating, the salts remained on the surface and were overpainted. Elemental analysis showed that the salt particles consisted of the typical ingredients of tap water such as calcium, potassium, sodium and chloride.

Example: attack on conversion layers

The formerly widespread green chromating usually survives the paint stripping process apparently undamaged. However, when investigating the paint defects on the aluminium strips described above, after removing the paint layer it was found that the chromate layer looked slightly stained and rough in the defective areas. The punctual damage to the layer can be clearly seen under the scanning electron microscope. The EDX analysis showed a significantly reduced concentration of chromium, oxygen and phosphorus compared to intact areas. The accumulation and drying of the rinsing water was therefore sufficient to damage the chromate coating. Due to their low layer thickness, conversion layers can generally be easily attacked during paint stripping. This is especially true for chrome-free coatings based on titanium and zirconium compounds. Even if the conversion coating is optically recognizable and obviously undamaged, it can be damaged in places. It should therefore only be used as corrosion protection for the intermediate storage of the stripped parts, but should always be removed and reapplied before recoating. Acidic pickling grease is suitable for removing chrome-free conversion coatings and dried salts. Dechromating is carried out with alkaline products.

Paint residues in corners and recesses

In some corners, depressions and undercuts, paint residues remain which are difficult to remove. The effect often occurs when the lacquer does not decompose in particles, but peels off in skin or flake form. The reason may be the choice of the paint stripping agent: alkaline activated products dissolve most paints in particles, whereas weakly alkaline to acidic products tend to cause skin or flake-like detachment. The chemical resistance of the paint also plays a role. For example, KTL usually dissolves in skin form even in alkaline-activated paint strippers at temperatures below 100 °C. Only in high-temperature paint strippers at temperatures above about 110 °C does rapid, particulate decomposition take place. In addition to increasing the temperature, a higher alkalinity can also promote the decomposition of the paint, provided that the substrate permits this.

Problems from other processes

Sometimes, the causes of defects are assumed to be in the paint stripping process, which actually originate in the manufacturing process of the parts or in the pre-treatment, but only become apparent after the paint stripping. These include, for example, partial unevenness of the surface caused by uneven pickling removal after inadequate degreasing or surface problems from the production of the substrate such as material removal from rolling, rolling in of cutting chips, accumulation of rolling aids or press fleas in profiles.

The complete article was published in German in the April issue of JOT.

Autor(en): Dr. Jürgen Silberzahn, Chemische Werke Kluthe GmbH