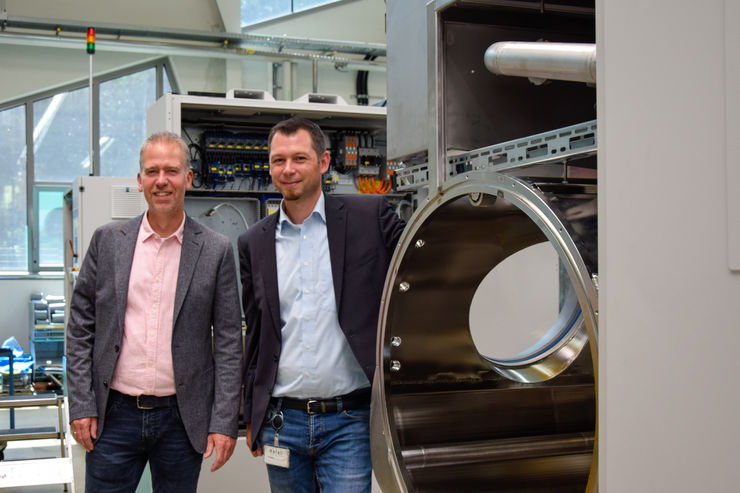

More than 50 years ago, the mechanical engineering company Mafac was founded in Alpirsbach. It was founded by Ernst Schwarz to manufacture belt grinders. In the mid-1980s, sons Joachim and Rainer Schwarz laid the foundation for kinematic aqueous parts cleaning with the first modular cleaning machine. They took over the management of the company in 1993 and made Mafac one of the world's leading technology manufacturers in the industry. The machines are used in almost all industries, mainly in the automotive and aerospace industries, in mechanical engineering, hydraulic technology, the electrical industry and metal-cutting manufacturing, as well as in medical and precision engineering. The hitherto unique operating principle of counter-rotation of the basket pick-up and spraying system, which underlies all Mafac machines, achieves a high cleaning quality. In April 2022, another generation change took place: Planned long in advance, it resulted in the management buy-out by the subsequent managing directors Stefan Schaal and Armand Oostendorp. Schaal is responsible for research and development, production, human resources and finance. Oostendorp is in charge of marketing, sales, customer support and product management. At 14 and 21 years old, both have been part of the Mafac family for a long time and feel a close connection to the company. "If we just wanted to make a lot of money, we would have sold the company to an investor. That would have happened relatively quickly. But what would then happen to the company in the long term is written in the stars. And that's exactly what we don't want," Oostendorp explains. "For us, the focus is on the employees and not on profit. Mafac remains a family business," Schaal adds emphatically.

Corporate strategy: organic growth

Compared to other companies, some of which cannot deliver their machines because a component is missing, Mafac is still very well positioned here. This is due on the one hand to the high standardization of the machines, which allows early material stocking, and on the other hand to the forward-looking actions of the company. This is also shown by their 5-year plan. The new managing directors and owners continue the previous business idea and focus on organic growth of the company. In doing so, the following priorities will be set: securing the location and jobs, measures to reduce costs, increasing added value, expanding and diversifying employee know-how, expanding production capacities and increasing the vertical range of manufacture. In addition, the continuation and expansion of research activities and the topic of sustainable production.

Opening up new markets

Due to the general structural change, Mafac wants to position itself more independently vis-à-vis the automotive industry or focus on other cleaning tasks in this area. "In the automotive sector, electric and hybrid vehicles are becoming increasingly important. This requires new, higher-quality processes in parts cleaning, which we can use for other industries at the same time. First and foremost, the medical technology sector," says Oostendorp. Here, Mafac has already formed a team and hired a product manager who is specifically responsible for this industry. Although Mafac already supplies equipment to the medical technology sector, the sales department now wants to approach the market proactively.

Read the complete article in German in the September issue of JOT.

Autor(en): Nadine Winkelmann, Deputy Editor-in-Chief JOT