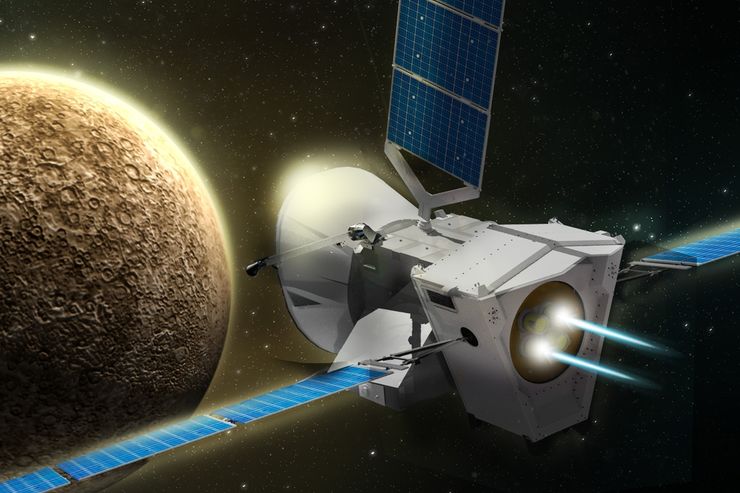

The European-Japanese BepiColombo mission to study Mercury started on 20 October 2018. It includes layers produced at the Fraunhofer Institute for Surface Engineering and Thin Films IST. Mercury is the smallest planet in our solar system, and at a distance of only about 58 million kilometres it is closest to the sun. As a result, the temperatures on the surface fluctuate extremely, with maximum temperatures of up to 430 °C and minimum temperatures of as low as -173 °C. The research probe is the closest to the Sun at a distance of only about 58 million kilometres. The BepiColombo research probe is expected to provide reliable data for more than a year, even under the most extreme conditions. One of the measures to protect against excessively high temperatures are titanium cooling fins coated with silver. A direct galvanic silver plating of titanium is very expensive: For the layers to adhere, the titanium must be pickled with hydrofluoric acid or other fluorine-containing chemicals. There is also a risk that the material will become brittle. Fraunhofer IST's solution is more environmentally friendly and more gentle on the material: The titanium components are coated with wafer-thin and adhesive copper in a vacuum using a plasma process. The titanium components copper-plated at the Fraunhofer IST were then galvanically silver-plated by a partner. In order to ensure that both coating processes and coatings meet the highest requirements, the entire production chain for coating deposition was developed and optimized at Fraunhofer IST. The combination of plasma technology and electroplating made it possible to simplify the entire process considerably.

(Ke)