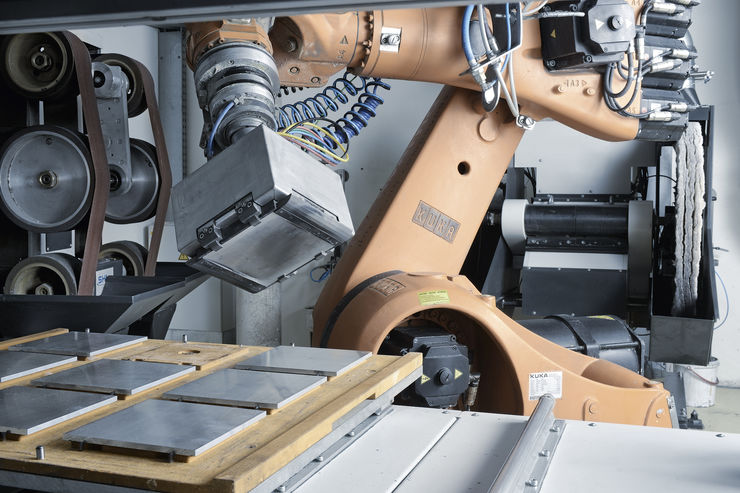

Process engineers are continuously working on making their polishing processes as economical as possible. They often make use of time-consuming in-house tests. Various polishing pastes and process parameters are run on expensive original parts on robot systems. Measures to improve the process can often only be derived from trial and error and are usually suboptimal. In most cases, there is uncertainty as to whether the chosen processes or polishing emulsions are actually the most economical. The choice of polishing tools, rings and pastes is often driven by pure price comparisons. However, the actual lever for cost savings lies in the process itself. However, due to a lack of measurement technology, resources and know-how, it is difficult to compare processes and polishing emulsions. Menzerna's so-called fingerprint process now offers a possibility for accurate and objective performance comparisons. The data generated with the aid of modern measuring technology provide information on, for example, stock removal rate, surface quality, cycle times, contact pressures, disc wear or workpiece temperature. On this basis, system parameters, polishing tools, polishing pastes, paste quantity or polishing times can be optimized.

Optimization based on valid data

The process allows extensive tests to be carried out with inexpensive sample parts. The standardised ground sample plates can be produced in large quantities from the original material. On the flat parts, the surface can be processed and measured much faster and more cost-effectively than on expensive original workpieces with complex geometries. The process parameters can be varied at will during polishing and can be analysed quickly, accurately and reproducibly with the test set-up. With the collected data, polishing processes can be significantly improved. Productivity increases of over 20 percent are possible. For the first time, the data determined with this method allow the exact description and visual representation of polishing processes with regard to removal and surface quality.

Autor(en): Menzerna Polishing Compounds