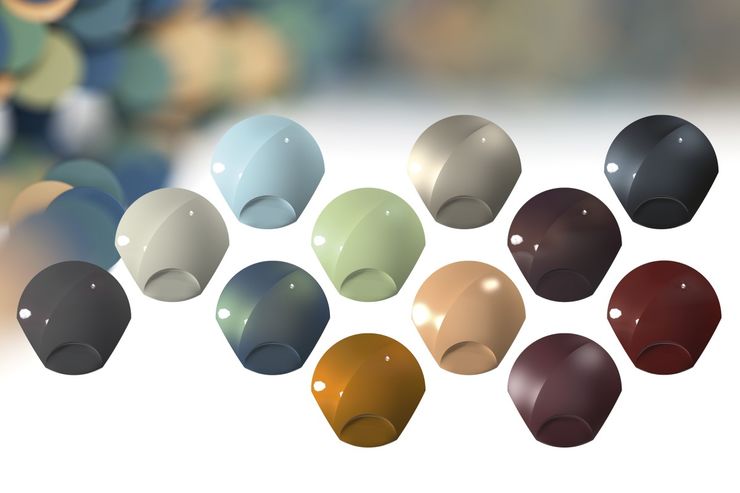

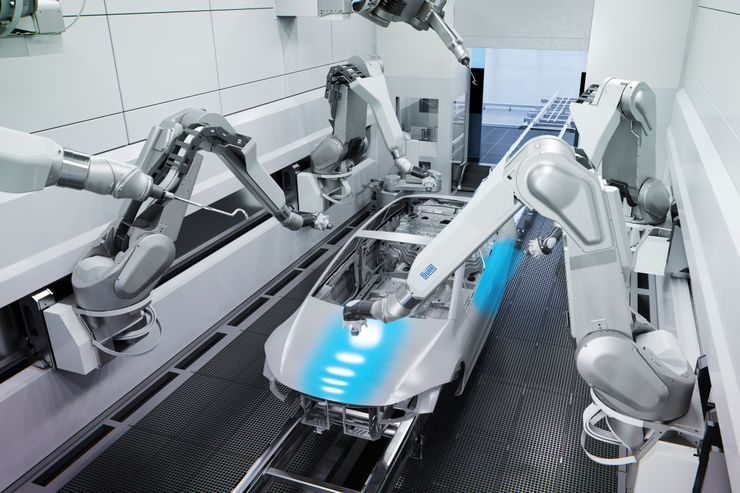

The BMW Group is the first car manufacturer to rely on more sustainable vehicle paints certified according to BASF's so-called biomass balance process. At its plants in Leipzig and Rosslyn/South Africa, the BMW Group uses the cathodic dip coating (CDP) Catho Guard 800 Resource produced by BASF's Coatings division, as well as the clearcoat iGloss matt Resource throughout Europe. By using these more sustainable product variants for vehicle painting, around 40% CO2 per paint coat can be avoided, resulting in a reduction at the plants of more than 15,000 t CO2 in the period up to 2030. "As the largest supplier of chemical products to the automotive industry, we are aware of our responsibility to support our customers with innovative and eco-efficient solutions. The biomass balance process allows us to make our surface solutions even more sustainable while maintaining the same quality. We are pleased that the BMW Group is a pioneer in the automotive industry and that our products are an important building block in achieving their ambitious sustainability goals," says Dr. Markus Kamieth, member of the Board of Executive Directors of BASF SE. "By reducing the use of fossil raw materials, we are conserving natural resources and at the same time lowering CO2 emissions. In doing so, we are increasingly focusing on sustainability innovations in our supplier network," says Joachim Post, BMW AG Board Member for Purchasing and Supplier Network. "The innovative paints based on renewable raw materials are an important step in this direction."

Autor(en): mak